Soudal polyurethane foam is a one-component polyurethane sealant manufactured by the company of the same name. The company was founded in 1966 in Belgium.

Today, the company has several branches on different continents. Products under this brand are shipped to more than one hundred countries. In the Russian market, Sudal polyurethane foam is one of the most demanded in the average price range. Consumers leave mostly positive reviews. Many people prefer to work with this foam.

Soudal polyurethane foam: technical information

1. Stable polyurethane-based foam.

2. Hardening occurs under the influence of moisture.

3. Initial hardening, when the sealant is covered with a film, after ten minutes (at an air temperature of twenty degrees and relative humidity of sixty percent).

4. Shrinkage and secondary expansion are absent.

5. The output of the foam from a cylinder with a volume of 1000 ml is approximately forty liters.

6. The hardened foam has a dense structure, where closed pores make up seventy to eighty percent. Density - about 26 kg / cu. m

7. The hardened sealant is heat-resistant (temperature range - from -40 to +90 degrees).

8. Sudal polyurethane foam does not flow during application.

9. Repulsive gas - propellant. It does not have freon. It is absolutely safe for the atmospheric ozone layer.

Characteristics of Sudal polyurethane foam

In the accompanying documents and on foam cylinders, manufacturers note the following properties:

high stability of the product (foam does not shrink and does not give secondary expansion),

- excellent filling ability

- excellent adhesion to most building surfaces (except polyethylene and polypropylene),

- very good sound and heat insulation characteristics,

- the presence in the line of products that are suitable for special and delicate installation work.

Scope of use of polyurethane sealant:

- installation and insulation of door and window frames,

- filling various voids in building structures,

- soundproofing,

- thermal insulation in cooling systems,

- filling sections of the passage of pipelines.

Soudal polyurethane foam is available in aerosol cans of 300, 500 and 750 milliliters, painted in the color of champagne. It should be stored in cool and dry places. Shelf life is twelve months. Foam must be applied on clean and moist surfaces.

Cylinders with polyurethane sealant are equipped with a special bayonet mount system. To fix the gun in the nest of the aerosol package, you only need to slightly press. Such a system simplifies the work of installers, allows you to quickly change cylinders.

Names of professional polyurethane foams for work in special conditions:

SOUDAFOAM CLASSIC GUN WINTER (winter mounting sealant that can be used at temperatures up to -10 degrees),

SOUDAFOAM CLASSIC GUN WINTER (winter mounting sealant that can be used at temperatures up to -10 degrees),- SOUDAFOAM MAXI ARCTIC (innovative and improved version of winter foam, withstands frost up to twenty-five degrees),

- SOUDAFOAM GUN LOW EXPANSION (foam with minimal expansion designed for delicate work),

- SOUDAFOAM GUN LOW EXPANSION CLICK & FIX (also foam with a small extension and a bayonet mount system),

- SOUDAFOAM MAXI (high yield polyurethane sealant).

Soudal polyurethane foam reviews

The bulk of consumers respond positively to the foam of this brand. Most often noted

- minimal expansion ("the foam does not increase very much when it dries, and subsequently does not come out of the seams"),

- cellophane gloves are included

- does not shrink,

- the foam output declared on the cylinder is true (almost always),

- defective products are very rare (in comparison with other foams in the middle price range).

Of the shortcomings are called

- foams marked "WINTER" have a lower output than stated by the manufacturer (at a temperature of -10 degrees).

That is, there are more positive reviews than negative ones.

Technical characteristics of Sudal polyurethane foam

Sudal foam is a material based on polyurethane. Hardening occurs in a humid environment. This composition has the form of a stable thixotropic foam, the cellular structure of which is characterized by the presence of 80% of isolated pores. The density of the material is 25 kg / m 3. This is true for solid mixtures. After 25 minutes, the material acquires a dry-to-touch structure, which is true at 20 ° C air and 65% relative humidity.

Foam "Sudal" after 8 minutes forms a surface film, which is true under the same conditions that were mentioned above. For a 3 cm gap, the cure speed is 60 minutes. About 70 liters should come out of one cylinder, which will depend on relative humidity and air temperature. The Sudal polyurethane foam is all-weather, the technical characteristics of which also suggest heat resistance, can be used in the range from -40 to +90 ° C. This is true for a completely solid composition.

The application temperature is in the range of +5 to +35 ° C. Specialists are sometimes also interested in the isolation factor, it is 35 mW / m · K. Fire resistance corresponds to level B3, while sound insulation is 58 dB. Shear strength is 17 N / cm², but the compressive strength is 3 N / cm². Moisture absorption is equivalent to 1%. Bending resistance is 7 N / cm².

Key Operational Features

Consumers like that the Sudal foam described in the article is offered for sale in a wide range, you can purchase professional and domestic materials. Foam can be designed for use in the summer and winter, and for ease of application, you may prefer pistol or manual options.

The material contains freon, which is environmentally friendly and lack of shrinkage. There is no double expansion effect. If you cannot choose between household and professional foam, you should know that the difference between these two options is only in the design of the cylinder valve.

Application Reviews

Soudal foam, according to customers, has a fairly wide area of use. It can be used when installing stairs, doors and window sills. The material proved to be excellent, according to customers, when attaching wall panels and sealing panel joints. You can purchase this composition for:

- filling the voids

- heat insulation fasteners,

- pipe fixing

- soundproofing screen formation.

Consumers, in their words, use the composition also for gluing roofing elements.

Usage Feedback

According to customers, the foam described in the article should be used according to the manufacturer’s instructions. If you familiarize yourself with it, you will be able to understand that the foam must be maintained for a certain time at room temperature before surface treatment. To improve the adhesion characteristics, the working surface must be additionally processed.

According to home masters, the surface should be cleaned of dust and dirt, and then moistened with water. Before starting manipulations, the protective cap must be removed, the gun connected, and then shake the container well. Sudal foam, the reviews of which you were able to read above, should be applied in the position of the balloon upside down. Excess material can be disposed of with acetone, Click & Clean or solvent. Frozen particles are removed mechanically.

The main properties of the material

The foam described in the article has high stability, it does not give secondary expansion and does not shrink. Among the abilities, excellent occupancy should be highlighted. Foam adheres to most building surfaces. It can be used for delicate and special installation work. Soudal foam, the technical characteristics of which were presented above, is sold in cylinders by:

- 300 ml

- 500 ml

- 750 mm.

The material is painted in the color of champagne. If storage is required, the containers should be placed in a cool, dry place. Shelf life is 12 months. For ease of use, the cylinders are equipped with a bayonet mount system. To fix the gun in the packing slot, a little pressure must be put on it. This system simplifies the work of craftsmen and allows for quick cylinder changes.

Reviews of the main varieties of professional mounting foams brand "Sudal"

Sudal polyurethane foam, the technical characteristics of which you must have studied before purchasing the product, as buyers emphasize, is sold in several varieties. If we are talking about professional options, you should pay attention to SOUDAFOAM CLASSIC GUN WINTER. This foam is suitable for winter installation work, because it can be used, as customers emphasize, at ambient temperatures up to -10 ° C. SOUDAFOAM MAXI ARCTIC is suitable for frosts down to -25 ° C. This product is improved, it is an innovative version of building winter foam.

If you need material with minimal expansion, then you should pay attention to SOUDAFOAM GUN LOW EXPANSION. This foam, according to customers, is designed to perform delicate installation work. The bayonet mount and minimal expansion has SOUDAFOAM GUN LOW EXPANSION CLICK & FIX foam. Consumers are advised to purchase SOUDAFOAM MAXI if you want to use a material based on polyurethane. In addition, this composition is characterized by an increased yield of the substance.

Features of Soudal polyurethane foam

The main features of Soudal polyurethane foam include:

- Universality of use (at home, during professional construction work, for work on the street, etc.).

- A wide selection of types of sealant with different characteristics, scope, life.

- The ability to use to create a heat-insulating and electrical insulating layer.

- High resistance to moisture, direct sunlight (UV resistance), corrosion processes.

- The dried sealant tolerates the effects of household chemicals and aggressive media.

Varieties

The Belgian manufacturer produces many types of Sudal polyurethane foam.

In the assortment you can find sealants:

- For winter, summer and all-weather use.

- For home and professional use.

In the Soudal catalog you can find several types of sealants that differ in characteristics and scope of use. You can list the most popular varieties.

Sonoud professional

Sealant with high performance. After hardening, it provides good insulation and noise insulation characteristics, perfectly fills microscopic pores and gaps. When hardening, it does not shrink and does not expand.

On sale you can find cans of volume:

750 ml cylinders are capable of dispensing about 60 liters of finished sealant. Such a mounting foam is used for sealing building blocks, filling voids in building structures. The use of a special gun for applying sealant is recommended.

Soudal Soudafoam Fr

Sealant for professional use, having a base in the form of polyurethane. Polyurethane foam consists of one component.

An important advantage of the products is a high level of fire resistance, therefore it can be used for treating various surfaces for which a proper level of protection against exposure to an open flame or high temperatures should be provided.

Flexifoam

Flexifoam polyurethane foam is not a standard sealant that could be used under normal conditions. This is a special product, the main field of application of which is structures that are subject to significant vibrational stresses, significant shifts and expansion load during operation.

The sealant is as flexible as possible (the most elastic in the entire line). When used, it protects structures from shock and vibration loads, good noise insulation properties, and reduces acoustic noise.

Soudal maxi arctic

The sealant is designed for use at low temperatures. It can be applied without preheating to various surfaces in outdoor conditions at temperatures up to -25 о. MaxiArctic polyurethane foam is designed for outdoor use, for use in cold stores and in any other places where the operating temperature is below zero. Use for ordinary home repairs is not recommended.

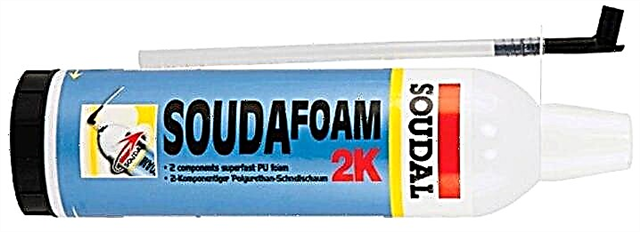

Two-component Soudal polyurethane foam

Two-component polyurethane foam is also in the catalog of the company from Belgium. It is characterized by quick solidification.

Scope of its use:

- Installation and sealing of wooden doors indoors (if mechanical fasteners are not used).

- Thermal insulation and noise insulation of ceilings and partitions.

- Filling and sound insulation of empty space in a closed profile (metal bathtubs, showers, frame structural solutions, etc.).

- Sealing during installation of door and window wooden, aluminum systems, PVC systems.

- Warming of elements of heating, plumbing, sewer systems.

The sealant is more suitable for professional use. Moreover, its application is fraught with some difficulties. In the description for the Sudal polyurethane foam the technical characteristics are presented:

- The minimum curing time of the applied composition (you can continue to work about 40-50 minutes after applying the mounting foam).

- High adhesion to wood, polymer, aluminum, brick, concrete surfaces.

- Increased density and high strength characteristics.

Scope of application

Sealant, depending on the variety, has a wide scope. Most often it is used:

- In the process of installation and the creation of a sealing layer in the building blocks (window and door structures).

- When fastening and fixing pipes (when installing sewer, heating, plumbing and other types of water pipes).

- If necessary, improve the performance of insulation of the cooling system.

- If necessary, gluing roofing and building materials (light weight) to various structures (roofing, ceilings, etc.).

- When aligning gaps, joints, seams, filling voids in structural blocks.

- To provide protection against liquid penetration into structural joints and profiles, to minimize the likelihood of mold and fungal lesions.

- To create a high-quality noise insulation layer in building structures.

- To create and fill a soundproofing layer in empty spaces of a closed profile.

- To fill the pipeline voids, as well as the free space that is formed during the installation of ceilings and walls.

- For fixing and sealing blinds, window sills, sills, steps.

- For mounting and sealing light wooden doors and other wooden structural and household elements.

The manufacturer from Belgium notes that the products are more specifically designed for professional use by repairmen, builders, installers and other specialists who constantly work with various sealants. For home use and minor repairs, such a mounting foam is also quite suitable, although buying it will be somewhat expensive.

Soudal maxi arctic

Soudal Maxi Arctic is a one-component polyurethane foam. It goes well with almost all materials, excluding silicone, polyethylene, teflon, polypropylene.It perfectly performs sound and heat insulation functions, has good filling ability and excellent mounting properties. However, its main advantage is the ability to use in frosts up to -25 degrees. It will not sag at such low temperatures.

This winter product is suitable for mounting and sealing door and window blocks, filling seams, creating soundproof screens. It can be used to insulate cooling systems. The cylinder will give an exit to 60 l of foam. Using a gun, you can dispense the amount of foam. And if you install a screw on the back of the gun, you can control the quantitative output of the foam.

Two-component

Soudal also produces two-component foams, in which the base and activator in the container are separated from each other, so they are stored longer than single-component foams.

Two-component foam hardens very quickly and cures well, while any humidity can be. It gives a greater yield than a single-component, has a wide range of applications, suitable for working with concrete, wood, metals, PVC and other materials. You can cut off the excess foam within 10-12 minutes after application. However, two-component foam is more expensive. In addition, due to the quick hardening of the cylinder, you can only use it once. Therefore, it is better that a professional work with this composition.

Where is it used?

Soudal foam is very widely used in various construction and finishing works, namely:

- indispensable when installing and sealing building blocks (doors and windows),

- necessary for smoothing joints, filling cracks and voids,

- glues insulating materials and roofing structures,

- improves thermal insulation of the cooling system,

- helps to fix pipes

- protects against moisture penetration into the joints of structures and profiles, preventing the appearance of mold,

- creates an excellent soundproofing layer.

- allows you to fill and create a soundproof layer in an empty space in a closed profile (under the bath, in the shower, in the frame structure),

- fills voids in the pipeline, in transitions when installing walls and ceilings,

- perfectly attaches and seals window sills and blinds, thresholds and steps.

- helps in installing and sealing lightweight interior doors made of MDF and other wood materials.

In the modern construction market there is a wide selection of different types of polyurethane foam, but not all products meet the quality requirements

Sudal polyurethane foam refers to the proven materials used in installation work. Soudal products are considered the best in Europe and have found application on the American continent.

Description

Soudal polyurethane mounting is a product of the development of one of the leading European manufacturers (Soudal) and compares favorably with its counterparts in increased adhesion to all surfaces (except for silicone, teflon and polyethylene), excellent sound and heat insulation characteristics. The lineup of products is represented by professional and domestic types, including pistol and hand foams, which are designed for use in the summer and winter. Sudal does not contain freon, is environmentally friendly, lack of shrinkage and the effect of double expansion. The difference between the professional and household series is only in the design of the cylinder valve to which the atomizer is attached.

Application area

The scope of use of SOUDAL foam is:

- installation of doors, stairs, window sills, windows, (Fig. 1)

- fixing wall panels and sealing between panel seams,

- pipe fixing, (Fig. 3)

- gluing roofing elements,

- the formation of a soundproofing screen.

Method of use

Before surface treatment, the foam must be kept for a certain time at room temperature. For better adhesion, the work surface is treated, cleaning from dirt and moistened with water. Before work, the protective cap is removed, the gun is connected, and the container is thoroughly shaken. Foam is applied with the cylinder upside down. Excesses were removed with acetone, solvent or a new Click & Clean cleaner, and solidified particles were removed mechanically.

Product Range (Fig. 4)

The most famous types of Soudal foam:

- SOUDAFOAM CLASSIC GUN - a professional series used in the temperature range + 5 ... + 30 ° C, the level of water absorption - 0.9%,

- SOUDAFOAM CLASSIC GUN WINTER - the product is intended for use in winter, withstands temperatures of -10 ° C,

- SOUDAFOAM MAXI ARCTIC - one of the latest developments of the company, allowing you to work at an environmental indicator of -25 ° C,

- SOUDAFOAM MAXI 70 - has a high fire resistance class B3,

- SOUDAFOAM MAXI SAHARA - is operated at a temperature of +40 ° C and above,

- SOUDABONDEASI - glues cotton, polystyrene, decorative materials to concrete, brick and metal surfaces.

- SOUDAFOAM FR and SOUDAFOAM FRCLICK & FIX foam belongs to the fire-resistant class and can hold fire for up to 6 hours.

& copy Build-Chemi.ru. Copyright protected

Subscribe

mail

MODERN BUILDING CHEMISTRY

SOUDAFOAM CLASSIC GUN WINTER (winter mounting sealant that can be used at temperatures up to -10 degrees),

SOUDAFOAM CLASSIC GUN WINTER (winter mounting sealant that can be used at temperatures up to -10 degrees),