What is cold welding? This question is asked by many of those who are going to use this tool for the quick connection of metals. Many people have no doubt heard about cold welding and a sufficient number of people have already managed to recognize all the advantages of this technology. But, unfortunately, not all of those home masters who already managed to try to connect metal parts using such a tool were able to appreciate all its unique characteristics.

Cold welding for metal

The main reason for this situation is that very often our people do not consider it necessary to carefully read the instructions, which stipulate all the nuances of using a particular device or technology. That is why we want to devote this article to all issues related to the rules of use and the scope of such a wonderful tool, which, undoubtedly, is cold welding.

Varieties of cold welding

In fact, cold welding is an adhesive with a high degree of plasticity, made on the basis of the well-known epoxy resin. By its structure, this glue can be two-component, then it can be stored for a long time, or one-component, which must be applied as quickly as possible so as not to collide with the loss of its adhesive properties.

Typically, such a tool is produced by manufacturers in the form of a two-layer cylinder, the outer shell of which consists of a hardener, and the inner core is an epoxy resin mixed with metal dust. Such an additive in the form of metal dust is necessary in order to give the resulting compound high strength and reliability. Contains cold welding and other additives that give it, as well as compounds obtained with its help, unique characteristics. Manufacturers keep the main part of such additives a secret, but sulfur is the most famous of them.

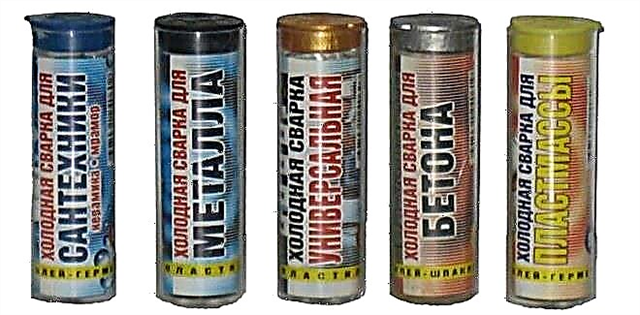

Cold welding is classified mainly by the area of its use, that is, by those materials that can be joined using its various types. So, today the following types of this tool are successfully used.

Cold welding for metal

Such a tool is actively and successfully used not only by home masters, but also by car enthusiasts, as it allows you to quickly and effectively solve many problems associated with the operation of the car. The compounds obtained with its help make it possible not only to forget about the problem for a short time, but also to operate the reconditioned parts for a rather long time.

However, it should be borne in mind that cold welding optimally shows itself when connecting those parts that do not experience significant loads during operation. Such a tool also found wide application in the repair of plumbing devices, in which it is necessary to quickly eliminate the leak. But no matter how reliable it is, you should always remember that it serves only to eliminate the problem that has arisen only for a while. At the first opportunity, capital repair methods should be used.

Cold welding glue for various types of plastic

This tool, which is less common, is used, as its name implies, for the operational repair of plastic parts. Such glue finds application both at manufacturing enterprises and for performing repairs in domestic conditions. Most often, the need to use such a tool arises in those cases when it is necessary to repair plastic pipes and cases of various devices.

Types of cold welding for various materials

You can also use such glue in those cases when it is necessary to connect products made of hard rubber. Naturally, such welding found wide application in the performance of construction and repair work. It should be noted that the linoleum compounds obtained with its help are significantly superior in characteristics to those for which glue or double-sided tape was used.

We have listed only the main types of cold welding, but there are others that are less common. All these tools are distinguished by high efficiency of receipt and reliability of the compounds, provided that when performing work they strictly adhered to all necessary requirements.

Application of cold welding for metal

Cold welding for metal, the instructions for use of which are in each package, is used in almost the same way as other varieties of such a tool. In order to understand how to properly use such glue, it will be enough to make out an example with the elimination of leaks in pipelines and tanks made of metal. What is convenient, this welding can be used both with empty and filled containers, and even those that are under low pressure. That is, for example, if you need to eliminate a leak in a car radiator, then it is not necessary to drain the liquid from it.

Detail after repair by cold welding

So, the algorithm for working with such glue is as follows.

- First of all, it is necessary to prepare the surface on which the glue will be applied. To do this, it is better to use an emery cloth, with the help of which the surface is cleaned from dirt and rust. This cleaning should be completed if metal has become visible on the treated surface with scratches applied to it with a skin. Moreover, the deeper and more frequent such scratches are, the more reliable the connection will be.

- Then dry the surface thoroughly. You can use an ordinary hair dryer for this, you will not need any special technical means. Of course, cold welding for metal will also cope with wet surfaces, but you cannot count on high reliability and tightness of such a connection.

- The next step, which will make the resulting compound more reliable, is the degreasing of the surface. To do this, it is better to use acetone, which will eliminate even minor grease stains on the treated surface.

- Next, we proceed to the preparation of the adhesive itself. Since this tool is not liquid, but rather dense, we use a knife to cut a piece of the required size from the cold welding cylinder. It is very important to cut strictly across the cylinder in order to preserve the initial proportions of hardener and epoxy in the resulting slice. The cut piece must be thoroughly kneaded until a soft and uniform color is obtained, and so that the product does not stick to your hands, you can periodically wet them with water.

The process of applying welding to the repaired surface

- After you have received a soft and uniform mass of the product, it must be applied quickly enough to the repaired surface. The technical characteristics of many types of cold welding are such that it begins to harden just a few minutes after cooking, so you need to act quickly, but carefully. If you seal the hole formed by cold welding, it is highly desirable that part of the soft mass get inside it. If such a hole is too large, then it is better to seal it with a metal plate, which is fixed to the surface using cold welding.

After the product is applied, it must be allowed to dry and completely solidify, which can last up to 24 hours. Only after this time the place of repair can be subjected to finishing (cleaning, filling and painting).

In any case, before you start using cold welding, it is better to read the instructions again or even watch the training video, which can be easily found on the Internet. It is very important to be careful when using degreasing agents, most of which are dangerous to human eyes and mucous membranes. In general, it is not difficult to use such a tool, and the compounds that it allows to obtain are distinguished by a sufficiently high reliability and tightness.

Scope of application

Cold welding allows you to glue almost any material, except for only very flexible ones.

Among the surfaces used, four groups can be distinguished:

- metals combined with homogeneous or dissimilar elements,

- any plastic except polyethylene,

- ceramics and glass, they are combined in any variation, there are no restrictions,

- any carpets and linoleums, it is possible to grip the floor or butt.

Apart are the plumbing work. The composition of the adhesive allows you to repair damage even with excess water on the surface, which significantly reduces the cost of repairing the heating system, water supply. The main quality of repairs carried out in this way is its durability. You can not be afraid that the patches on the pipes will not survive until the heating is turned off and the end of the season.

Due to the lack of such qualities as hygroscopicity, cold welding is used in a wide variety of repair work. If you have welding in a plastic form, then when mixing the components of the glue, this “clay” will cling to your hands. By wetting the surface of the hands before work, you will avoid this effect, the preparation of the composition will pass faster, and all this will not affect the quality of the result.

However, many experts recommend working with a dry composition, since the seam obtained in this way will last longer.

This glue is truly unique in its ability to grip the elements of the radiator or muffler of the car. Of course, such a repair does not replace a trip to a service center or a trip to the store. With this putty you can’t make a power seam, but it’s easy to close a hole in a couple of centimeters.

A patch of such glue will last you quite a while. It is resistant to temperature effects and mechanical damage, so it will not ignite and will not burst during the trip.

It is undesirable to use cold welding in the cold, because it will be quite difficult to soften the adhesive composition.

Composition and characteristics

Cold welding is a one or two component adhesive, having approximately the following composition:

- as a base - various resins providing flexibility,

- as a filler - crushed metal to a state of powder,

- as additional materials there are various types of sulfur and more.

The main parameters of the quality of the repair are determined by the composition of the adhesive, the quality of cleaning of the bonded surfaces and the method of its application. In theory, you can try to achieve a weld hardness comparable in quality to the adhesion of metals in conventional welding, but most often the resulting weld is significantly inferior to the conventional method. Therefore, this adhesive should not be used in case of serious damage.

The temperature maximum that will withstand the resulting seam depends on the composition of the adhesive. Often, it is indicated on the package, and if everything is done correctly, the patch will gain strength and heat resistance.

Cheap welds hold temperatures up to two hundred fifty - three hundred degrees, but there are also those that will not fail at one thousand three hundred and fifty degrees. Particularly heat-resistant compounds are used in the repair of parts subject to strong friction, high temperatures, or when it is simply impossible to use conventional welding.

Cold welding is a special type of glue that can harden in a short time and avoid reactions with motor oil or other combustible elements of the car. The glue adheres perfectly to a variety of metal surfaces.

The variety of welding offers on the market is represented by several types.

- Spot welding is a method that allows you to bond products made of soft metals like aluminum, brass or copper. In everyday life, it can be pan handles or fixing copper plates on aluminum wires for reliable contacts.

- Suture welding - is widely used to create hermetically sealed objects such as the case of any device or vessel. For work, contour punches are required.

- Butt welding is the main way to connect electrical cables.

- T-welding - used for fastening brass studs with aluminum leads, transformer windings and so on.

- Shear welding - designed to connect heating and water pipes.

On the market, glue is available in two possible options.

- In liquid form, its base is epoxy, which slowly hardens in combination with a hardener. The composition is used in conjunction with a metal mesh or fiberglass. When applied to bonded surfaces, the adhesive does not leave unpleasant odors or secretions.

- In a plastic form, the glue is presented in the form of a dense mass pressed into bars. In this form, it is used as a putty, resembling children's plasticine.

Manufacturers

Choosing a repair composition home or for a car, you need to familiarize yourself with a number of adhesive parameters:

- types of surfaces interacting with glue,

- the maximum and optimal temperature loads that the adhesive can withstand,

- the contents of the instructions for use.

When choosing a repair composition, many experts recommend paying attention to samples of popular brands. Often, the aggregate opinion of the end users can provide more complete information about the product than the opinion of an individual specialist or consultant in the store.

Among the popular brands, the following have proven themselves in the market:

Products of well-known brands are much more expensive than their unknown counterparts, but you can rely on them in a difficult situation.

Advantages and disadvantages

One of the main advantages of cold welding is its composition. Its active elements do not contain organic or synthetic substances hazardous to humans, they do not emit toxic fumes. The smell emanating from the putty when used is absolutely safe for the respiratory tract.

Main advantages:

- when connecting metals, they are not damaged, since heating is not used,

- the resulting seam is neat and reliable,

- sometimes it’s only possible when it comes to adhesion of soft metals or explosive elements,

- having completed repair work, there will be no metal waste left

- the method is environmentally friendly and does not harm the environment,

- work does not require special skills or tools.

There may be one drawback. A danger can be the ingress of glue elements into the human digestive system - in this case, if symptoms of poisoning appear, it is recommended to consult a doctor. In order to prevent the composition from entering the body, performing work of grinding or drilling of hardened glue, special protective equipment should be used: a mask and glasses.

How to use?

Types of cold welding vary in composition and curing periods. Among the offers on the market there are options sharpened to interact with specific surfaces.

Some samples in an elastic form can retain their quality even after complete hardening, so it is especially well combined with various delicate decorative surfaces. It becomes indispensable in the repair of plastic pipes.

Before applying to the surface, the adhesive mass is thoroughly mixed.

The final connection of the elements takes about half an hour later, which gives the necessary amount of time to give the object the desired shape. Finally, the workpiece hardens after one and a half to two and a half hours.

This glue is perfect for furniture repairs in the garden or garden. It is not worth it just to repair damage to gas tanks and cans with combustible substances, since often it contains powder-ground steel that can cause static sparking and ignition.

One of the most unusual areas of its application has been the restoration of the surface of picture frames. Putty perfectly copes with scratches of any severity, cracks and indentations. To cope with damage from mold or fungus. It is used both for internal and external decoration, it will serve much better than wood, prone to decay and other negative effects.

Its most popular use among customers is the coupling of metal surfaces. Its corrosion resistance and rust immunity are especially appreciated.

Thus, this welding method can be widely used in the repair of movable furniture elements, various items of forged and cast metal.

Reviews

When looking at the totality of reviews on the network for various types of weldings, it becomes clear how irreplaceable this is. The authors of the reviews are both men and women, which indicates the ease of use and the breadth of applications. Most often they write about affordable prices. Sometimes they just describe their specific use case. Many note its indispensability in the cottages, where there is absolutely no way to invite a professional welder. Cold welding was tested when repairing furniture, water tanks, metal utensils, iron gates and even broken gas tanks of cars (although this is very dangerous). The vast majority of users recommend this item for purchase.

See how to use cold welding in the next video.

What is cold welding and what is it

Cold welding is a special type of high-strength adhesive, which is used to connect various materials, including steel. The composition is based on epoxy glue or resin with different fillers, due to which high strength of connection of parts is ensured. It is not always possible to achieve high quality compounds, therefore, many complain and refuse to further use the material. The reason is not at all the poor quality of the glue or its low efficiency, but the non-compliance with the instructions for using the composition.

In order for cold welding to provide the desired reliability of the connection, an appropriate approach is needed for its application. Before using cold welding, it is necessary to understand the features of its proper application. After the appearance of high strength adhesive, various manufacturers began to produce it. In order to save on production, some manufacturers violate the standards for manufacturing cold welding, which ultimately affects the quality of the joints. To avoid this, you need to buy welding only with quality certificates that guarantee the effectiveness of the material.

Cold welding is classified into two types:

And both types of glue present an epoxy substance, as well as fillers - sulfur, metal powder and other compounds. According to the type of composition, cold welding is dry and liquid.

Dry welding of two components is in a cylindrical package. When it is necessary to use the product, the components must be mixed to obtain a mixture similar to plasticine. It is very convenient to work with plasticine, therefore, it is possible to provide a connection by cold welding of dry type even in the most inaccessible places. The effectiveness of the material depends on the quality of the kneading composition. Both components must be used in the same amount and mixed thoroughly.

Liquid welding also consists of two components, which are epoxy and hardener. These components should also be combined together before immediate use. The quality and reliability of bonding depends on such factors as thorough mixing. The more thoroughly the substances are mixed, the more reliable the junction.

Cold welding is also classified according to the method of application, which depends on the set technological tasks:

- Suture - is used to create a durable and impermeable seam when it is necessary not only to connect parts, but also to ensure their tightness. Suture composition is suitable for cases when it is necessary to prevent the flow of metal pipes, etc.

- Spot - such glue is applied in dots, which allows to achieve high reliability, but there is no tightness. It is used mainly in exceptional cases when it is necessary to ensure the connection of two parts

- Butt joint is a special type of glue that is used to join metal parts by joining them. When using butt welding, it must be understood that only thin metal can be bonded with such glue

- T-shaped - this type of adhesive is used exclusively in electrical installation

- Slide or lap welding - glue used to combine pipes of different diameters. Using sliding glue, you can connect pipes of different diameters, but only by overlapping

Where applicable

To connect two metal workpieces, you can use a welding machine. However, this tool is quite expensive, but even if you buy it, you will need to learn how to use it before use. It is also necessary to learn how to use cold welding, only training is much easier and simpler than with a welding machine.

In addition to the fact that cold welding is used to connect metal parts, it is also used to restore the integrity of other materials. The scope of use of the connector in question is quite wide, and welding is used in the following cases:

- When repairing vehicles, these are special substances that are used directly to repair cracks, old joints, as well as to attach parts to the body base

- When connecting parts subject to high temperatures. For this, special heat-resistant adhesives are used. In addition to resistance to high temperatures, such materials must be resistant to differences in which the expansion and contraction of metals

- When performing connecting work in the plumbing sector - it is used to seal and seal pipe damage points, as well as to overlap them. The main requirement for cold welding for plumbing is moisture resistance

- For concrete - if there is a crack in the concrete, then the ingress of moisture and debris will lead to an increase in the size of the defect. To prevent further destruction of the material will help a special composition for concrete

- Universal - allow you to connect all kinds of materials, such as plastic, linoleum, metal, plastic and others

Before you learn how to use cold welding, you need to choose the right tool for joining certain materials. In everyday life and the economy, the need for cold welding arises to perform such tasks:

- Connect heating pipes

- Eliminate leak due to leaky pipe

- Close up any holes in the dishes

- Seal the chimney connection with the boiler outlet

- Glue different parts, interior items, etc.

Sooner or later, everyone needs to use cold welding, so it is recommended not only to buy high-strength glue, but also to learn how to use it. Having understood the types and features of high-strength glue, you can find out the principle of working with cold welding.

Instructions for the use of cold welding

When buying cold welding, you must read the instructions for the use of adhesives. Each tube or package contains instructions that you need to read even if you are sure that you know how to use it correctly. When using glue called “Cold Welding” there are no difficulties, but you need to know the application features. Let's consider in detail how to use the component when connecting different materials.

Welding Features

Cold welding - highly plastic glue. It is made on the basis of epoxy resin with a two-component structure. Characterized by a long shelf life. It is also used one-component, which must be applied very quickly, since it dries.

Today on the market are sold compounds that withstand high temperatures. From this and the name high-temperature cold welding. At a price they are not the cheapest, but are considered a good solution if other types of welding are not feasible for certain circumstances.

Cold welding is operated not only by people who independently make repairs in the house, but also by motorists. The parts fastened in this way will serve for a long period, only in the absence of constant loads.

User guide

Use this substance in accordance with the manufacturer's advice, which are shown in the instructions. Using it is quite simple, so it is possible to connect, including cracked glass. For these purposes, there is colorless welding.

To make a reliable seam, it is necessary to correctly observe the following rules:

- Training. It is recommended to free the work surface from contamination and remove large protrusions. Wet parts with the ability to properly pre-dry. It is imperative to degrease parts. This is a very significant step, which guarantees the ultimate quality of the connection.

- Next, you need to prepare the composition. Liquid glue must be combined with the hardener, and dry welding must be mixed to a homogeneous composition. When mixing, use disposable gloves pre-moistened with a small amount of water.

- After preparing the consistency, you need to quickly apply it.

- After painstakingly connecting the components, it is necessary to level the plane. After complete drying, you can additionally clean the seam.

Here is a similar simple technique can be indispensable in domestic use, which, following the instructions, is not inferior to classical welding methods.

Welding different materials

Welding for plastic

This welding option is rarely used. This use can be explained by the fact that for bonding plastic parts it is better to use a special gun - fastening with hot glue. Despite the fact that cold welding for metal is better known, welding for plastic is still used. It will be needed in those cases if there is no glue gun or if it is not possible to plug it into a power outlet. This glue instantly fastens the parts.

Cold welding for metal

You can repair plumbing fixtures, and specifically to eliminate leaks. However, no matter how strong it is, it is always necessary to remember that it serves only to eliminate the problem that has arisen only for a while.

Welding for wood

It is used by builders or wood experts. With the help of this type, it is possible to eliminate the formed cracks.

Aqua welding

This type is suitable for gluing surfaces that are constantly in contact with water. With it, you can not only fill deep cracks, but also glue 2 large-sized parts. Aqua welding is used in the work of plumbers for gluing batteries, pipes, ventilation.

Cold welding for linoleum

It is applied when, it is necessary to carry out the connection of products made from hard rubber. Of course, such welding found extensive use in the performance of repair work. It should be noted that the linoleum compounds obtained with its help significantly exceed those of their own characteristics for the performance of which glue or double-sided tape was used.

Tips from experienced welders

For the best adhesion of parts, it is recommended to apply glue on a wet surface. The method is more in demand in problems with pipe leakage. Therefore, when performing repair work, you can not block the water.

There are some useful tips to remember:

- When repairing pipes and pipeline components, it is necessary to buy an exclusively moisture-resistant composition, taking into account constant contact with the liquid.

- If you have to urgently close up a leak in a plastic pipe, you need to change a similar patch later - the adhesion will be poor.

- For faster hardening of the mass, you can use a hairdryer with warm air.

- It is worth buying only funds from trusted manufacturers.

- Do not use expired material.

Pros of cold welding:

- There is no heating, which means that the metal structure will not change.

- You can make a durable seam.

- Cold welding can be used in emergency explosive and fire hazardous areas.

- For the performance of work there is no need for special training.

Conclusions

- Before use, the surface must be prepared: cleaned and sanded. When there is a paint coating - it must be removed, when there is rust - treat it. After that, it is necessary to degrease the surface, it is possible, for example, to use a solvent.

- The welding kit itself involves 2 rods of plasticine-like substance, which should be mixed immediately before use. If you do not mix the composition on time, then after about thirty minutes it will begin to stone.

- Mix the composition with your hands, kneading like plasticine.

- You can apply the finished cold welding by hand. However, for convenience and the most careful look, you can use spatulas, pre-soaking them with water.

- The repaired part must be immobilized for approximately thirty minutes.

- Final hardening occurs in a day. After that, the surface can be treated like ordinary metal.

Summing up, it is worth noting that cold welding is a unique method of joining metals of different composition and strength. Its use implies the observance of certain specific conditions, but this does not prevent users from using it everywhere, while speaking positively about its characteristics.

How to glue glass

To glue cracked glass, you will need to use transparent glue. If everything is done correctly, then after finishing work on the glass no traces will be visible. Instructions for using transparent cold welding for gluing glass are as follows:

- First you need to prepare the surface. The effectiveness of gluing glass depends on the quality of the preparation. The glass surface should be cleaned of dirt and degreased.

- When the surface is ready for gluing, it is necessary to start preparing the adhesive composition. If a liquid consistency is used, then the substance combines with the hardener.When using dry welding, you need to combine the substances and mix them until a homogeneous consistency is obtained. When working with liquid glue, you will need to use improvised means, eliminating contact with the skin. Dry welding can also not be taken in hand, so work must be done with medical gloves

- After the mixture is ready for use, it should be applied immediately. It is impossible to leave the composition for a period of more than 3-5 minutes, since the adhesive properties are reduced, and the agent hardens

- Connect the parts and press them firmly. Leave on for a while until the composition dries. Typically, the drying time is indicated by the manufacturer on the packaging. When the composition completely hardens, you can begin to clean the adhesive seam

In such a simple and quick way, you can glue the glass using cold welding. The connecting seam is strong enough, therefore, even when breaking the glass, you can observe such a picture that it does not crack at the place of gluing.

How to connect linoleum with cold welding

One of the most popular queries in Yandex and Google is the rule of gluing linoleum using cold welding. Floor linoleum is popular, and therefore, when laying it in large rooms, it becomes necessary to glue the joints. For this, special cold welding for linoleum is used, and the process of gluing two sheets is carried out according to the following scheme:

- First you need to ensure perfect joining of two sheets of linoleum. This is achieved by overlapping two parts with an overlap, with a protrusion of at least 5 cm. This protrusion is needed so that the junction does not have free space. The overlap must be glued with masking tape, and then with the help of a sharp construction knife to remove the upper and lower parts of the protrusions of linoleum. It is not necessary to glue with masking tape, but it is recommended, since at the same time the joint will not move. This simple method achieves high precision joints.

- At the next step, you also need to use masking tape, and glue the joint on both sides from the bottom and top. Gluing the lower part is also not necessary, but this will eliminate the adhesion of linoleum to a moisture-proof film. Top masking tape sizing is performed in order to prevent cold welding from getting on the decorative part of the material

- At the point of joining, you need to cut a line in the adhesive tape, through which cold welding will be introduced

- Pick up a tube of special glue for linoleum, and apply it to the joint with a thin needle twisted on a tube. If the glue will go beyond the connection, then it should be promptly removed with a tampon

- In addition to this method, there is another one, which consists in the fact that a uniform layer of glue is applied to one end part of linoleum, and then it is laid and connected to the second sheet. This method is suitable if the junction has an almost imperceptible seam that does not allow a thin needle to pass along it.

The curing time of the glue is at least 2 hours, so it is recommended to withstand this time, and only after that to remove the masking tape. If there is a protrusion of glue in place of the seam, then it can be removed using a clerical knife or a spatula.

We glue the heating pipes by welding

When using cold welding for heating pipes, it must be borne in mind that a special heat-resistant composition should be used. If this requirement is neglected, then at the first temperature increase the weld seam will crack, and water from the system will continue to ooze.

To repair the heating system in the event of a leak, it is necessary to use a dry type of cold welding. The principle of its application for the repair of metal heating pipes is as follows:

- Water must be drained from the system. If the place of application of the substance is wet, then talk about quality in this case is not necessary

- It is imperative to clean the repair site from paint and rust removal, as well as to degrease

- Dry the surface

- Knead cold welding, and carefully glue the necessary amount of substance to seal the leaky part of the pipe

- Wait for drying, and only then can the system be filled with water

The use of an adhesive composition for sealing damage to steel heating pipes provides for the following recommendations:

- The thickness of the dry composition should be negligible, since the quality of adhesion of the substance depends on it

- The diameter of the damage should be no more than 5-6 mm. The larger the diameter of the hole that is sealed by cold welding, the lower the reliability of such a connection. If it is necessary to seal a large hole with cold welding, it is rational to use a metal patch

- After the material has dried, the pipe surface can be painted.

You must also understand that in this way it is possible to seal heating and water pipes with a slight pressure of up to 1 atmosphere. The greater the pressure, the lower the effectiveness of the use of the substance in question. In a similar way, you can close up not only the heating pipes, but also the batteries. A video is shown below, which shows that before you make repairs to a heating system or water supply system that are under pressure, you need to think carefully.

Results of the correct application of cold welding

Regardless of which materials are glued by cold welding, when using this composition, it is necessary to take into account the main requirements in order to obtain a reliable connection:

- Thoroughly clean, scrub and degrease the surfaces on which the composition is applied.

- Properly prepare the adhesive. To learn, it is recommended that you first practice

- Apply and thoroughly smooth the composition on the surface for 1-2 minutes after preparation

- Wait until the product solidifies

Guided by these recommendations, it is possible to glue cold-welded metal, plastic, linoleum, plastic, plumbing and other materials. When dried, soft plasticine or glue (depending on the type) becomes oak, and in strength resemble impact-resistant plastic.

Even if you understand and know how to use cold welding, then reading the instructions and watching the video will never be superfluous. When acquaintance, you can find out some nuances that will help to avoid mistakes. In the end, it should be noted that the use of the tool in question allows you to quickly, inexpensively and effectively eliminate minor defects yourself. Of course, cold welding will not be able to replace a full welding joint, but it will always help out with minor defects. And correctly, you need to not only be able to prepare and apply the mixture, but also decide on the use of this composition to eliminate defects.