Official website of the exclusive importer and distributor of METALOTERM chimneys (Metalotherm) in Russia

Buy chimney - This is a very responsible matter. First of all, the most important question should be asked: is the safety of the chimney guaranteed after the second soot ignition? Our answer: with Metaloterm® AT chimneys / Metalotherm AT - YES!

Designed and manufactured by the Dutch company ONTOP, the Metalotherm AT series chimneys are the world's first fireproof modular chimneys with a manufacturer's warranty 30 years even after repeated soot ignitions in the chimney (t> 1000º C)! Available since 1982.

Metaloterm chimney systems (Metalotherm) - dChimneys of increased reliability and safety.

You can select and calculate a chimney for a fireplace, boiler or stove in salons "Fireplaces and stoves FLAMBIS / FLAMBIS". Installation of a pipe for a fireplace or stove requires a special license.

What is it and what is it for?

Chimney - a system of pipe channels designed to exhaust smoke and gases generated during the combustion of fuel into the atmosphere.

The main requirements for chimneys:

- resistance to high temperatures (more than 500⁰C),

- the formation of sufficient traction

- complete tightness

- resistance to moisture generated inside the system as a result of condensation,

- resistance to the effects of carbonic and sulfuric acids formed inside the circuit as a result of the chemical reaction of water vapor and exhaust gases (soot),

- ensuring structural stability,

- compliance with fire safety standards.

How is the chimney

Despite the fact that the structure of smoke channels made of different materials has its own characteristics, in general, they are a vertical, inclined, or horizontal airtight shaft adjacent to the combustion chamber of a heat generating unit (fireplace, stove, or boiler).

The section of the pipeline can be round, oval, rectangular and even polygonal. Height - at least 5 meters.

Each wiring diagram is individual and is selected depending on the specifics of the building and fireplace model.

Principle of operation

- The fuel placed in the firebox of the fireplace (furnace, boiler) is ignited, as a result, the process of generating heat starts, and with it the smoke (soot, ash and other aggressive chemical compounds harmful to human health).

- The temperature of the combustion products is about 500⁰C, which means that they become lighter and rush up the mine. The inflow of cold air starts the process of natural convection, increasing the traction force and thereby expelling the combustion products to the outside.

- Oxygen-saturated air naturally supports fuel combustion.

Traction force

The operation of the chimney is based on the draft effect, due to which the masses of gases move in the direction from the pipe inlet to the outlet due to the influx of fresh air from the outside. Traction force is a variable value, weather conditions influence it: wind direction and speed, outdoor temperature, as well as the state of ventilation in the room (fresh air flow).

Signs of traction problems:

- difficulties in kindling a fireplace,

- slightly burning flame

- smoke in the room.

To check the smoke shaft for natural cravings, a lit candle or match is brought to the furnace of the idle fireplace:

- the inclination of the flame towards the smoke exhaust channel indicates the correct operation of the circuit,

- if the flame is level, there is no traction,

- inclination of the flame towards the room warns of the effect of reverse traction.

It is impossible to operate the fireplace in the absence or reverse draft. Too strong traction leads to a decrease in heat efficiency and a meaningless overspending of fuel.

Causes of traction problems:

- incorrect flue duct configuration

- insufficient height or improperly selected section,

- chimney clogging,

- lack of fresh air from the street.

The conditions for the normal functioning of the chimney:

- maximum contour verticality

- smoothness and tightness of the walls,

- regular maintenance and cleaning of the chimney,

- installing a baffle above the pipe,

- providing fresh air (the presence of a separate adjustable air duct from the street or installing window fittings in the ventilation mode during the operation of the fireplace),

- installation of equipment to provide forced traction.

Types and designs

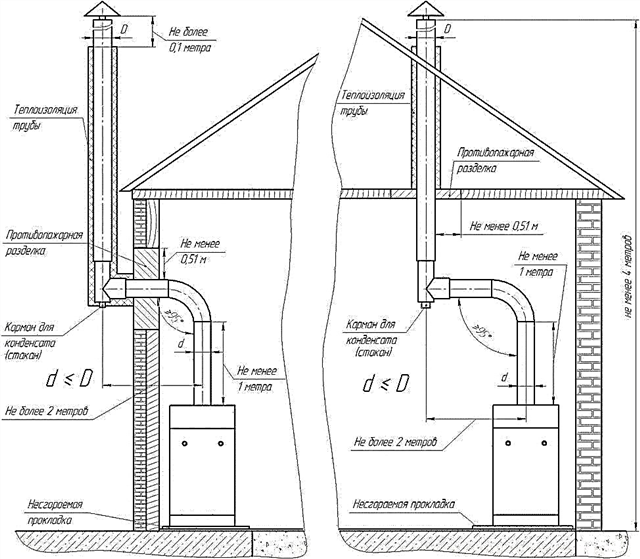

At the location of the chimneys are divided into external and internal.

- Placing a chimney inside a heated room and its output through the roof.

This method allows you to naturally increase traction, protect the chimney from freezing and reduce the coefficient of heat loss. In addition, the lack of reference to the external wall makes it possible to install a fireplace in any part of the building, while maintaining maximum verticality, and the gradual cooling of the air mass prevents the formation of condensate inside the circuit. However, the location of the chimney inside the house, firstly, occupies a usable area. Secondly, it does not always look aesthetically pleasing (unless it is made of brick). Thirdly, with errors in the arrangement of the smoke exhaust channel or improper care of it, the probability of fires increases.

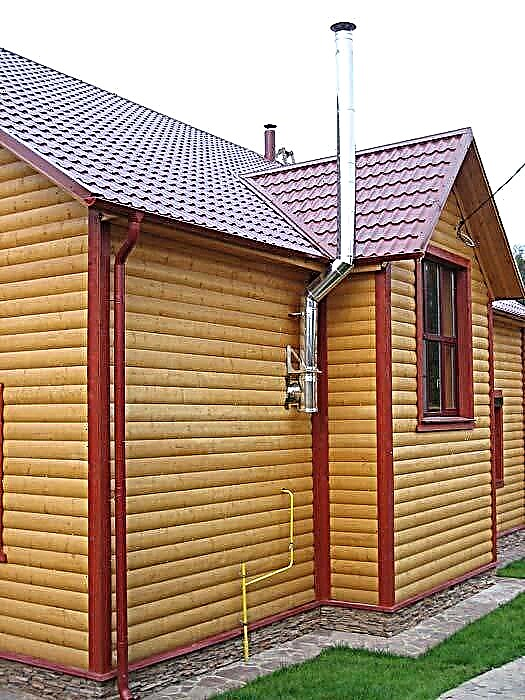

- External placement of the chimney pipe.

The heater is placed near one of the front walls, and the pipe itself is carried out through this wall. This concept allows you to increase the useful area of housing, which is especially important with the small size of the house. However, the pipeline circuit requires careful insulation, which still does not solve the problem of the formation of condensate in it, the cause of which is a significant difference in the internal and external temperatures. A negative point is the inevitability of laying part of the pipeline in a horizontal position, which reduces traction and makes it difficult to clean the main line. The location of the chimney channel on the street significantly reduces the risk of fire, and therefore is considered safer. In addition, it is easier to equip and repair.

According to the type of design, chimney circuits are divided into:

- indigenous, in which the chimney channel is arranged on a separate foundation and attached to the fireplace in a vertical position on the side.

- Mounted, installed over the fireplace and being its natural extension.

- wall, when the chimney is placed directly in the internal or front wall of a private house or through it goes out.

To equip chimney shafts, a variety of materials are used that meet the following requirements:

- high coefficient of heat resistance and fire resistance,

- low thermal conductivity

- inertness to aggressive chemical compounds formed from combustion products,

- resistance to water and corrosion processes.

The conditions indicated above correspond to the following types of materials:

The material is affordable and traditionally used for the construction of stoves, fireplaces and chimneys to them. However, not every type of brick is used for this purpose, but only full-bodied clay, which has passed the preliminary firing stage, due to which it is able to stably withstand the effects of high temperatures. Subject to all construction technologies and proper care, the brick chimney has been used for over 100 years.

Special requirements are also imposed on the cement mortar, with the help of which brick is laid. It should be a mixture of sand, cement and lime in a ratio of 5: 2: 1. It is such a solution that can provide a tight, sealed connection that is resistant to heat. Because the smoothness of the inner surface of the pipe is one of the paramount requirements for the arrangement of the chimney channel; the mortar to be laid must not protrude from the suture joints inward. However, a certain roughness is inherent in the brick surface itself, which causes settling on the walls of ash and soot, which eventually leads to the appearance of congestion.

The significant weight of the structure requires the pouring of a separate deep foundation, which means that the construction of a brick chimney must be planned at the stage of preparing the project for building a house.

Ideal for wood and other solid fuel fireplaces. It resists high temperatures (up to 1000⁰C) and the aggressive influence of chemical elements. Ceramics quickly heat up and slowly cool down, which can significantly save energy when heating a house. The perfectly smooth surface of the inner walls prevents the accumulation of combustion waste inside. Service life - 30-50 years.

A variety of shaped elements allows you to implement almost any design solution. In addition, pipes alone are not enough, a special mounting glue will be needed, with the help of which the elements are assembled and sealed, as well as the construction of a heat-insulating circuit from heat-resistant materials. Manufacturers suggest using specially designed lightweight aerated concrete blocks for this purpose as a heat-insulating circuit, often additionally equipped with a heat-insulating layer.

Among the shortcomings, the heavy weight of the structure, requiring the installation of a separate foundation foundation under the chimney, and the high cost of the structure, should be noted. When using lightweight concrete blocks, the need for a traditional foundation disappears, it can be completely replaced with a monolithic base from a concrete pipe.

Chimneys made of heat-resistant anticorrosive steel are used only at combustion temperatures not exceeding 400⁰C. They are much cheaper and lighter than brick and ceramic counterparts, so there is no need to equip a foundation site for them. Their service life ranges from 15-20 years.

Metal pipes are manufactured in factories in separate sections, from which the circuit of the desired configuration is then assembled. Depending on the type and rigidity of the metal, they can be self-supporting or requiring additional fixation to other supporting structures (walls, trusses, etc.) made of one type of metal or several (stainless steel inside, aluminum outside). The main advantage of steel chimney channels is the ease of installation and connection. In addition, they can be installed both independently and in combination with brickwork, carrying out the so-called shelling.

Steel chimneys are classified into 2 groups: simple without insulation and sandwich pipes, the design of which provides for the presence of a heat insulating layer. The coaxial design (“pipe in pipe” + thermal insulation) is most popular.

Durable tempered glass is not the most practical solution for a chimney, and most often it is used exclusively for decorative purposes. As pluses, it is worth noting the absolute inertness to the chemical effects of combustion products and the perfect evenness of the walls, which prevents the formation of soot growths inside the contour. Nevertheless, it is necessary to wash the visible areas quite often, since small deposits of soot still form, which negates the aesthetic appeal of such a chimney.

The complexity of the assembly in terms of ensuring the tightness of the joints is one of the main disadvantages of this type of design. In addition, glass is prone to condensation and requires work on the insulation of the circuit. All this, combined with high cost, makes glass not the most popular material for arranging chimney pipelines, assigning it the role of a decorative element only in a small area of the contour.

In a number of technical documents for the installation of chimneys, the use of asbestos-cement pipes is allowed. However, experts do not recommend their use for this purpose, because they are characterized by insufficient resistance to high temperatures (no more than 300⁰C).

Monolithic concrete is used on an industrial scale, but for private home ownership this method is considered too time-consuming.

Forbidden to use:

- tree,

- silicate and hollow bricks,

- clay,

- galvanized sheet.

Which fireplace is better

The choice of material for the flue duct should be based on the technical characteristics of the fireplace and the fuel on which it will work:

- for solid fuel fireplaces, brick or ceramic pipes are best suited

- for gas models, priority can be given to coaxial steel pipes.

A few recommendations for choosing the type of design:

- It is best to install a chimney inside the house, where the operational load on it is minimized. In addition, this solution will allow you to generate heat coming from the chimney shaft into useful energy for heating your home. However, it should be understood that this is the most time-consuming process and sometimes not feasible in the conditions of an already constructed building.

- Installation of a fireplace with the conclusion of the smoke circuit to the street is possible at any stage of construction and even upon completion.

- With the internal location of the chimney shaft, it is best to take a place under it in the middle of the room or on one of the internal walls. Thus, more heat will be stored indoors and the likelihood of condensation forming inside the circuit will be reduced.

- Choosing one of the facade walls, care should be taken to thoroughly warm the structure from the side of the street. To do this, either the brickwork is thickened, or special fireproof materials are used.

- A cylinder is the most optimal form of the chimney channel, providing maximum traction due to the flow movement in a spiral. A similar effect is also characteristic of oval, square and rectangular shapes, but at a lower speed. In addition, soot will inevitably accumulate in the corners, which further degrades traction.

Do it yourself or order

At first glance, there is nothing difficult to install a chimney with your own hands, however, this is not entirely true. First of all, it should be remembered that the design must be absolutely safe, which means it must be durable, airtight and with good traction. And this will require the “stove-maker” as a minimum, appropriate knowledge and thoroughness, and as a maximum, certain experience and skills.

On the other hand, entrusting such a responsible work to a builder whose professionalism and integrity you doubt is not the most reasonable decision. After all, poorly performed work in the future can result in a fire or carbon monoxide poisoning.

Therefore, preference should be given only to trusted construction companies or to take on the job yourself.

But for independent implementation of the project, maximum efforts will be required:

- to study a number of building rules and technical information about the heater,

- make the necessary calculations,

- carry out construction and installation systematically, often for a long time and with special care.

Building Standards

The rules for installation and operation of chimneys are regulated by a number of building standards:

- SNiP II 35 / 2.04.05-91 / 2.01.01-82,

- DBN V.2.5-20-2001 and NPB 252-98,

- GOST 9817-95, etc.

- combining ventilation and chimney is not recommended,

- adjoining the chimney circuit to other communications: electrical wiring, gas main, etc., is not allowed

- for each gas equipment, a separate smoke exhaust channel must be equipped,

- when two fireplaces (not gas) are located on the same floor, they can be connected in one smoke exhaust shaft with its mandatory separation by a transverse wall at a height of 75 cm,

- the mine is installed primarily vertically (verticality is mandatory for gas equipment). The maximum permissible deviation coefficient is 30⁰, while the inclination diameter should be equal to the cross section of the main vertical contour. The number of pipe bends cannot be more than three, and the length of the horizontal areas should be within 1 meter, with a total of no more than 2 meters,

- the minimum height of the pipe is 5 meters from the grate to the extreme point,

- the optimal speed of air flow is 15-20 m / s.

- to remove soot deposits in the base of the contour it is necessary to equip special "pockets" with a depth of at least 25 cm,

- sagging of the pipeline circuit is not allowed, for this purpose all its parts must be hermetically joined together, and the pipeline itself is attached to the supporting elements of the structure,

- to prevent precipitation from getting inside, the pipe is closed with an “umbrella” from above.

Chimney height requirements:

- For a gable roof: at a distance from the ridge (parapet) to 1.5 m - from 50 cm, at a distance of 1.5-3 m - not lower than the height of the ridge, at a distance of more than 3 m - not lower than the edge of the line drawn at an angle 10⁰ from the roof parapet to the horizon.

- For flat roofs - more than 1.2 m.

- When removing the pipe through the wall - from 1-1.5 m from the ground.

Requirements for the room in which the installation of the fireplace is planned (SNiP 31-01-2003 / 31-106-2002 / 41-01-2003 / 42-01-2002 / 42-101-2003):

- Ceiling height - at least 2 m.

- Volume - not less than 7.5 m³.

- The presence of a quality ventilation system.

Fire safety requirements for chimneys

A fireplace and a chimney to it are sources of increased danger. Therefore, compliance with fire safety measures is the main condition for the implementation of their installation and operation.

- The sections of the floor, walls and ceilings in contact with the chimney are insulated with refractory materials (metal, asbestos cement, plaster, basalt wool, etc.).

- The thickness of the insulating layer is at least 13 cm for sandwich chimneys and 25 cm for single-wall.

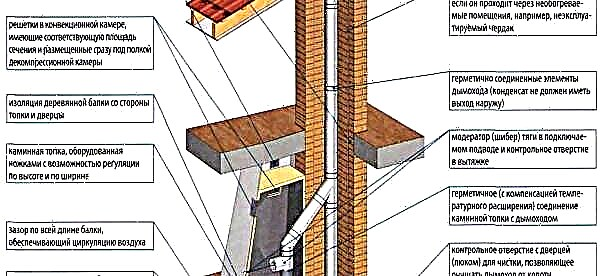

- In the area between the cladding and the ceiling, a convection chamber is installed with a thermal screen and ventilation vents.

When using fireplaces and chimneys it is forbidden:

- Fire with flammable liquids and other flammable materials and substances.

- Use firewood that exceeds the size of the combustion chamber for kindling.

- Use a chimney to dry clothes or shoes. Q = C A 2 g H T i - T e T i < displaystyle Q = C , A , < sqrt <2 , g , H , < frac <>-T_

><>>>>>>

DIY chimney manufacturing and installation

Deciding to make a chimney with your own hands, first of all, you should:

- determine the material from which the structure will be made,

- to make a drawing and a diagram of the future structure,

- calculate size.

There is no universal construction scheme for the chimney design, it will be individual for each chimney, because depends on a number of factors:

- features of the room where the installation of the fireplace is planned, and the structure as a whole,

- type of heater

- type of fuel used

- selected building material (coefficient of its thermal expansion).

Regardless of the above aspects, the work must be carried out in accordance with construction standards, fire safety requirements and recommendations of manufacturers of thermal equipment.

What materials are better to make

Initially, the choice of material is based on the type of fireplace used and only then on the aesthetics and personal preferences of the owner.

- Brick chimney is recommended for use only with solid fuel equipment.

- The symbiosis of brick and gas fireplace is not the best solution, because the temperature of the processed combustion products of gas appliances is quite low. This leads to the formation of a large amount of condensate, which, entering into a chemical bond with the combustion products, destroys the brick structure. The same applies to liquid fuel, pyrolysis (gas generating) or pellet (automated solid fuel) fireplaces.

If masonry is a prerequisite for you, you should make the liner (lining) of the chimney channel, i.e. install a single-layer stainless steel pipe inside, which is resistant to acidic conditions. The advantage of the metal insert is that it can be inserted into the chimney even after completion of construction work or during the reconstruction of an old mine. At the same time, a distance must remain between the wall and the steel liner.

On a note! Lining is an excellent solution in cases where the channel is not straight or has non-standard sizes.

- When choosing an iron chimney, one should take into account their fire resistance coefficient when working with various types of fuel. So for coal fireplaces it is better to use AISI 310/309 steel with an operating temperature of up to 1000⁰C, for wood - AISI 430/439 (up to 900⁰C), for gas - AISI 321 (up to 700⁰C).

Drawing and schemes

The scheme of the device of a metal sandwich chimney:

Drawing of a traditional brick chimney mine:

Brick chimney layout with steel / ceramic insert:

Size calculation

When carrying out design calculations, the required cross-section and pipe height are determined. This takes into account:

- fireplace power

- type of fuel

- Placement

- climatic features of the region.

When the result is lower than the height of the house, it is adjusted upward, taking into account regulatory standards for height (at least 5 meters) and the required level of elevation above the roof.

In addition, the following recommendations should be followed:

- the diameter of the chimney must be equal to the diameter of the outlet of the fireplace,

- the diameter of the chimney shaft while simultaneously connecting two units to it is calculated separately for each and summed,

- when rounding into a turn, the radius of this rounding shall not exceed the cross section of the main contour.

To determine the necessary parameters, knowing the power of the heating unit, you can use the table:

To maintain optimal heat transfer and circuit safety, the wall thickness of the pipeline is of no small importance. The following minimum values are set depending on the type of material:

- for brick construction - 12 cm,

- for concrete - 6 cm,

- for steel pipes - from 1 mm.

Mounting Features

- Installation is made from bottom to top.

- The modular pipeline is assembled by introducing one pipe into another, the joints are additionally treated with refractory sealant and fixed with clamps.

- The pipeline is attached to the supporting structure with special brackets every 2 meters, avoiding deflections and constrictions.

- In the areas of ceilings and "roofing cake" can not be placed connecting seams. In addition, the so-called "fire cutting" is performed here in 150 or 300 mm for pipes, respectively, with and without insulation.

- If the roof belongs to the category of combustibles, a spark arrestor made of metal mesh with 5 × 5 mm holes is mounted on the pipe.

- The walls around the chimney shaft are necessarily lined with fire-resistant material (clinker, tile or iron sheets).

- With a horizontal outlet of the circuit through the wall, revision and cleaning modules are installed in them.

- To prevent the ingress of sediment and debris, weathercocks and baffles are installed on top of the pipe.

Common installation errors and problems

- Defect in the structure of the chimney.

Excessive slope, a large number of bends and their incorrect radius, the presence of horizontal areas and the excess of their permissible length weaken the traction in the circuit and contribute to the formation of soot growths in it.

In the case of a complex-loop brick chimney, it is quite difficult to correct the situation, sometimes the sleeve or the installation of forced-type smoke exhaust equipment (smoke exhaust) solves the problem. If this is not possible, the structure will have to be disassembled and redone.

The modular steel structure of the open type is easily disassembled, which means that it will not be difficult to remake it.

With a pipe height of less than 5 meters, traction is significantly reduced. If the ventilation and smoke exhaust pipes are located in the same module and the height of the latter is insufficient, the risk of drawing gases back into the ventilation increases.

The error is corrected by building the chimney to the required level.

- Too small or large cross-section.

Not only reduces traction, but can also damage the integrity of the circuit as a whole.

The draft is corrected by installing a weather vane or turboprop on the chimney head protecting the circuit from blowing and the effect of reverse thrust in windy weather. However, in calm they will be useless.

- Unsuitable material and construction defects.

The material must comply with the technical parameters of operation, and installation is carried out in strict accordance with the standards.

Neglect of these issues threatens to melt the coating or burn it and, as a result, fire.

Maintenance and cleaning

Preventive maintenance and cleaning of the chimney canal is carried out at least 2 times a year, before the onset of the heating season and at the end of it. The check should be carried out by representatives of regulatory organizations, they also make a conclusion on the suitability or unsuitability of the chimney circuit for operation. With the appropriate knowledge and skills, the home owner can also periodically inspect it. In this case, the channel is checked for:

- traction

- partition integrity,

- tightness of the circuit,

- the presence of blockages.

When the ash thickness is more than 2 mm, cleaning is performed. To do this, use a special weight-ball, a ruff and a hard brush with an elongated spread handle or on a steel cable. Starting cleaning from above and gradually spreading the handle, they advance into the shaft depth. Previously, the fireplace insert is closed to prevent soot from entering the room, furniture is covered, windows and doors are closed.

Cleaning can also be done using chemistry. The so-called "miracle logs" during combustion emit chemical compounds harmless to humans, under the influence of which carbon deposits lag behind the walls.

Once every ten years, major repairs of brick structures are carried out, replacing the solution in the joints.

It is forbidden to burn soot and use chlorine-based cleaning products.

Expert Advice

A few tips from experienced "stove-makers":

- Do not place chimneys in corners and places of intersection of walls, so as not to weaken their strength.

- Before laying a brick smoke channel, an orderly (layer-by-layer) scheme of its laying should be prepared.

- The laying of otters and lumps, which are an integral part of the brick structure, can be reinforced with metal rods or plates.

- Do not smooth the internal roughness of a brick pipe with clay. This provokes the appearance of condensation and dampening of the brick.

Device and principle of operation

Chimneys for fireplaces or stoves are channels through which a mixture of gases, which are products of fuel combustion, is removed from the furnace of a heater to the atmosphere. The design of these elements of the heating system is carried out in the form of a pipe or a brick shaft, the tightness of which determines whether the system works correctly. Chimneys for fireplaces and stoves are necessary, since without them it is impossible to operate heat-generating devices, the operation of which is as follows:

- Fuel is placed in the furnace of the heat-generating equipment (stove, fireplace, boiler). Basically, appliances operate on wood, gas, compressed or coal, fuel oil.

- The fuel is ignited using an open flame source, as a result of which the system generates a large amount of heat, which is used to maintain the optimum room temperature, and smoke.

- Smoke, which is a product of fuel combustion, consists of a mixture of carbon dioxide and carbon monoxide, ash, soot, and other aggressive chemicals. The temperature of the smoke entering the chimneys for fireplaces or stoves reaches 400-500 degrees, therefore, obeying the law of convection, it rises, freeing up space in the furnace for cooler air.

- The design of the smoke exhaust channels is a vertical sealed shaft, along which hot smoke rises only up. Thanks to this process, fresh air saturated with oxygen, necessary for maintaining combustion, enters the furnace.

The process of sucking oxygen-rich air into a firebox is called draft. To check the chimney flues for the presence of draft, you need to bring a lit match or candle to the firebox: if the flame deviates towards the smoke exhaust channel, the system works correctly. If the flame of the candle burns evenly, they say that there is no traction. But the most dangerous situation is the formation of reverse thrust, it is signaled by a flame that deviates in the opposite direction from the chimney.

In order to correctly make a smoke exhaust channel for a stove or fireplace, you need to carefully study the information on the heating device specified in the instructions, as well as calculate the volume of gas in the furnace. It is quite difficult to mount a chimney for a fireplace with your own hands, since this complex design requires special knowledge and experience, which only experienced craftsmen can boast of.

Placement Methods

The assembly and connection of the smoke exhaust channel occurs after installing the heater. However, you need to choose a place and calculate the cross-section and height of the chimney before starting the installation. Chimneys for fireplaces or stoves are placed in two ways:

- Internal placement. This placement method involves the installation and connection of a smoke exhaust channel inside a heated structure. On the territory of Russia, the chimney of the furnace was traditionally placed in the house, leading to the street through the roof. Installing the channel inside allows you to protect it from freezing, as well as reduce heat loss occurring in the area passing along the street. In this case, the calculation is made that while the smoke is moving through the pipe, it gradually cools, so that condensation does not occur. The traditional internal method of placement has 1 negative side: a pipe, especially a brick, takes up a lot of space in the room. In addition, it increases the risk of fire.

Note! The calculation of the smoke exhaust channel of the heater determines the recommended cross-section and height of the pipe, calculates the required draft level to maintain combustion. When calculating these parameters, the device power, type of fuel used, location and climatic conditions in the construction region are taken into account. Chimneys for fireplaces are built on the basis of a project that takes into account all of the above factors, and the connection is made under the supervision of a professional craftsman.

Materials

Chimney flues are made of various materials that have high heat resistance, low coefficient of thermal conductivity, excellent refractory properties, do not enter into oxidative reactions with water, and do not interact with aggressive chemicals that are contained in the composition of combustion products. To make a durable and reliable smoke exhaust channel for the furnace, the following materials are used:

- Brick.It is a traditional material for the construction of stove chimneys, as it has excellent heat resistance, does not burn and, if properly maintained, lasts more than 100 years. For the construction of the pipe, a solid, burnt brick is used, the cost of which is higher than simple silicate brick. This method is one of the most expensive due to the high price of the material, the need to fill a deep foundation. In addition, it is unlikely that you can make a brick chimney and make a connection to the stove with your own hands, you will also have to spend money on hired craftsmen, whose services are expensive. A brick shaft has a rectangular or square section, so in the corners and on the rough surface of the material, soot and ash settle, leading to the appearance of congestion.

Important! The material for assembling the chimney is selected based on the type of fuel that the heat generating device is running on: for fireplaces and stoves that run on solid fuel, brick and ceramic pipes are better suited, steel sandwich pipes do a good job of smoke removal from gas models.

Smoke exhaust duct requirements

The use of heating partitions is associated with the risk of fires and carbon monoxide poisoning, therefore strict requirements are set for smoke exhaust channels, the task of which is to protect users. In order to ensure that the operation of the equipment does not cause problems, the following conditions must be met when installing the chimney:

- The pipe diameter is selected in accordance with the size of the inlet pipe of the heat-generating equipment. If the pipe is larger, the connection between them will be leaking, which can cause carbon monoxide leak.

- Places for connecting, laying and passing pipes through walls or floors are insulated with refractory material, which prevents overheating of the finish. For these purposes, use metal or asbestos cement.

Important! Experienced stove masters advise when discussing the design of the fireplace to insist on placing a chimney inside the house, and this is necessary at the inner, and not the outer wall. With this installation scheme, the channel turns out to be warmer, there is no deficiency of draft and vapor condensation.

The disadvantages of brick structures

A chimney for a fireplace made of bricks has drawbacks, the main of which is the short operational life of such structures, which does not exceed 7-10 years. The fact is that frequent and significant changes in temperature during the cold season lead to the appearance of condensate, and it either freezes or thaws. As a result, over time, the brickwork begins to collapse.

To reduce the impact of negative moments, you can:

- expand the cross section of the external chimney walls to 25 centimeters in those places where they are above the roof surface,

- to insulate these sections of the chimney with mineral plates.

The chimney pipe will last longer if you install a cap on top of it that protects against precipitation.

One of the significant drawbacks of chimney structures made of brick is the presence of a rough inner surface, since this circumstance leads to a decrease in thrust efficiency compared to smooth pipe walls.

The design of smoke discharge through a chimney, which has a certain margin of cross-sectional value, can help to cope with this problem. Installation of galvanized steel pipes inside the flue system will also increase the duration of the operational life.

Types of chimney pipes

For the manufacture of a chimney of a fireplace, various materials are used. There are several main types of pipes:

Each material has its own properties that affect the operation of the duct. A chimney is necessary for most types of fireplaces, with the exception of an electric fireplace. Since smoke is not emitted during its operation, and the action is based on the illumination of the fog with the help of LEDs, the chimney in the electric fireplace performs only a decorative function and can be made of any material.

Stainless steel chimney designs

Chimneys for foci of this type are stacked structures. The length and diameter of the pipe for a fireplace made of stainless steel can be very different. Such products are often produced complete with ceramic and placed inside steel.

Chimneys made of galvanized stainless steel have the following advantages:

- they can be mounted without foundation, because they are lightweight,

- assembly and installation of the structure is allowed to be carried out after completion of construction

- they are cheaper in cost than block and ceramic systems,

- if necessary, replacing individual elements will be easy.

Chimney selection criteria

When deciding which pipe should be near the fireplace, you should first pay attention to the cross section. The choice of this parameter depends on the type of unit or fireplace. The chimney is equipped, taking into account the parameters 140x140, 140x270, 270x270, which are multiples of the size of the brickwork.

The diameter of the chimney flue cannot be less than this parameter at the boiler exit. And it, in turn, depends on the type and power of the unit.

The vent vent hole is located close to the chimney structure. According to the norms prescribed in SNiP, an exhaust hood is installed for boiler rooms, which is able to provide triple air exchange per hour. For living rooms with fireplaces, ventilation is sufficient, creating a twofold value of this parameter. The best solution would be to place a chimney pipe surrounded by ventilation ducts.

Among other criteria, when calculating the chimney pipes, the type of fuel used is taken into account. If it is liquid or gaseous, then the wall thickness should be at least 0.6 millimeters. When it is planned to use solid fuel, the required wall thickness of the structure is 1 millimeter.

When arranging a chimney inside a brick mine, single-walled components are used. If the smoke exhaust structure will be located separately in the house or outside the building, it is necessary to use insulating materials that ensure fire safety. When a fireplace in a wooden house is planned to be heated with coal, chimneys with an insulation thickness of 50 to 100 millimeters are chosen.

When purchasing elements for arranging ceramic or steel smoke exhaust systems, attention must be paid to the limits of the permissible temperature regime. If it is planned to use firewood or coal for a fireplace, then pipes that are designed for a fuel combustion temperature of up to 250 ° C cannot be used - they are intended exclusively for gas or oil units.

When choosing a chimney, attention is paid to the following points: is it possible to use it in furnaces operating on solid fuel, and on the resistance to possible ignition of ash at a temperature close to 1000 ° C.

The chimney for the boiler should look like a vertically arranged homogeneous structure. The height of the chimney pipe can not be less than 4-7 meters with an optimum draft of 10-20 Pa (in more detail: "What height of the chimney is needed above the roof - norms and rules").

According to the requirements for operation, chimney cleaning and control over their condition must be carried out by chimney sweeps at least 4 times during the year.

Fireplace brick pipe

For the construction of chimneys, chamotte solid brick is used. It is a refractory material that withstands extreme temperatures. The service life of such an duct with proper care can be quite long.

When erecting a chimney duct from a brick, there are several nuances. The chimney pipe is combined with a ventilation riser in one heavy construction. Because of this, a solid foundation is needed. As a support, a supporting wall or base plate can be used.

A chimney for a fireplace from a brick is made in the form of a rectangle or square. Blocks of material are connected using a sand-lime mortar. Anchors are used to strengthen the pipe. They are installed in the chimney to a depth of not less than 20 cm. To avoid destruction of the brick pipe, it is necessary to reinforce its walls. Brickwork is reinforced with reinforcement every third row.

The brick is good in that it can easily withstand extreme temperatures

The brick is good in that it can easily withstand extreme temperatures

The disadvantages of fireplace chimneys made of brick include:

- the high cost of the material

- the need to fill a thick foundation layer,

- soot and ash accumulate inside the duct due to the rough structure of the brick,

- the rectangular shape of the chimney leads to the appearance of congestion, due to which the pipe needs constant cleaning,

- uneven walls cause poor draft in the chimney, due to which smoke enters the room,

- destruction due to condensation in the pipe.

For masonry to serve as long as possible, it must be insulated in vulnerable areas. As a heater, mineral plates can be used.

Steel chimney

Another popular type of chimney pipe is the so-called sandwich pipe. This name is due to the fact that the chimney is a prefabricated structure of several elements. Two stainless steel cylinders of different diameters are inserted one into the other, a layer of thermal insulation is placed between them. A stainless steel fireplace pipe is excellent for removing smoke from gas models of foci. It can be connected to the centers from various material. For example, to cast-iron fireplaces.

Sandwich pipe for the chimney between two layers of steel has a layer of insulation

Sandwich pipe for the chimney between two layers of steel has a layer of insulation

The service life of the steel chimney is about 20 years. Unlike a brick pipe, the stainless steel duct is made in the shape of a cylinder. This increases the draft from the fireplace. Steel is a smooth material, so soot and ash do not settle on the walls of the pipe in such quantities as on brickwork.

Stainless steel is an affordable and relatively cheap material. The steel chimney is lightweight and does not need to build an additional support. This is one of the most economical options for chimney pipes. Another advantage of the steel chimney for the hearth is the possibility of installing it directly after all construction work. Significant disadvantages of stainless steel pipes include an unappealing appearance, which is why in private homes for the pipe you will need additional decoration.

Ceramic fireplace duct

Ceramic pipes for the fireplace, in which the price and quality of the product are ideally combined, are especially popular. Ceramic chimney is a structure of several pipes and concrete blocks. The life of such a pipe with proper care is about 30 years.

As is the case with stainless steel pipes, a ceramic duct does not need to build an additional foundation. Pipes are made of lightweight concrete blocks. Blocks are connected and reinforced with reinforcement. Inside the blocks is a ceramic pipe. Often, between the blocks and the pipe, an additional layer of thermal insulation is laid. It is necessary if the fireplace is powered by solid fuel and the heat exceeds 400 degrees.

Ceramic chimney for a fireplace does not require additional foundation

Ceramic chimney for a fireplace does not require additional foundation

Ceramic pipes for fireplaces have some of the best indicators of traction. They are easy to assemble and quick to install. It is also one of the most durable types of chimneys. Due to the presence of special holes in concrete blocks, it is possible to easily clean the pipe from blockages. Also, gaps are used to prevent condensation from accumulating inside the ceramic pipe.

Enamelled chimney pipe

Enameled chimney is a pipe made of carbon steel and several layers of protective enamel. Enamel protects the metal from corrosion and damage. The coating holds well heavy metals and toxic fumes, preventing them from penetrating out through the chimney.

As a heat-resistant enamel, two types of coating are used - primer and top coat. Hardening of the coating occurs during heat treatment. The pipe is fired at a temperature not lower than 900 degrees. As a result, the metal and enamel form a tight connection.

Enameled chimney pipes can withstand temperatures up to 500 degrees. The disadvantages of the material include fragility of the pipe. Such a chimney must be installed with great care, since any mechanical impact can damage the material.

Rules for installing a chimney pipe

It is necessary to install a chimney for a fireplace, taking into account fire safety standards. There are basic recommendations that must be followed during installation:

- The joint of the pipe and the fireplace itself must be completely tight. It depends on where the smoke will go during the combustion process. The diameter of the pipe should not exceed the diameter of the inlet pipe of the fireplace. If this principle is not respected, there is a danger of carbon dioxide entering the room.

- The passage of the chimney pipe in the house should be isolated from the finishing materials. Materials such as asbestos cement, basalt wool and sheet metal are used as fire protection. The distance from combustible materials must be at least 13 cm for a multilayer type of pipe and at least 24 cm for a single layer. For brick pipes, it is necessary to use a thickened type of masonry and additional insulation from asbestos cement at the joints with the home decoration.

- It is advisable to install the chimney strictly upright. No more than three bends in the structure are allowed. If there is a need for horizontal installation of the pipe, such a section should occupy less than one meter. Otherwise, the draft of air from the fireplace is disrupted.

- The size of the pipe affects the draft in the chimney. The minimum height from the source of combustion to the head is 5 meters.

- The chimney should protrude at least 50 cm above the roof of the roof. If the roof is sloping, you should focus on the highest point.

- The distance between the tip of the chimney and the ridge should be about 50 cm. If the pipe is discharged through the wall, a minimum height of one meter from the ground must be observed.

- So that condensate does not collect inside the pipe, and there is also optimal draft, it is advisable to install a chimney pipe near the inner wall of the house, and not bring it out onto the street. The material from which the chimney is made will also last longer, as it will not be affected by the external environment.

Thanks to these recommendations, the installation of the pipe will be performed as safely as possible, and will also create good air draft in the chimney.

Possible problems in the operation of the chimney pipe

The operation of the fireplace largely depends on the correct installation of the chimney. If insufficient draft occurs, check the calculations by which the chimney was built.

The chimney pipe is not installed correctly if:

- smoke enters the room

- kindling a fireplace takes a long time,

- the fire in the fireplace burns too weak

- The burning rate of solid fuels is constantly changing and depends on weather conditions.

The causes of the chimney malfunction are as follows:

- Insufficient pipe height. The larger the fireplace, the higher the duct should be in order to provide a sufficiently strong traction.

- In the design of the pipe there are bends of more than 45 degrees. It is advisable to make the chimney as straight as possible. If horizontal elements are still present, it is worth choosing the minimum angle of inclination. The vertical part must be at least 5 meters.

- Incorrect calculations. In many respects the draft depends on the correct section of the chimney.

- External influence. Weather conditions can affect the draft intensity in the pipe.To prevent this, it is necessary to install a weather vane in the chimney.

The chimney pipe must be installed in accordance with all standards. This will make the fireplace fireproof, and also ensure its proper operation.